Here at Scott’s Home for Orphaned Smart Hoops we’ve welcomed some well-known orphans like the Photon and the Synth and more obscure ones like the elusive

Omega Infinite and the ultra-rare Mobius HD, but our latest arrival is the rarest of them all: the only example of a Prodigy Hoop known to exist outside of its creator’s rural Kentucky hideout.

I’ve posted teardowns of many smart hoops on The Hoop Review group on Facebook. Usually I have only the hardware and I’m working backwards to guess at the story behind it, but this hoop’s arrival was preceded by more than two years of hype, rumors, and leaks. The project began with a heavily-promoted Kickstarter campaign started by Jonathan Clark. The campaign was successfully funded exactly two years ago and brought in $95,838 in pledges from 381 backers with the first deliveries expected the following month.

Three models were announced: the entry-level Protege, the top-of-the-line Tesla, and the modular Houdini. Only the Protege was offered through the Kickstarter. The design was supposedly finalized before launch and promised impressive specifications, including a 168 MHz ARM processor, high reliability, a price tag half that of the competition, and an unprecedented 3-year warranty.

It’s important to note that just about all of us who have gotten into making smart hoops have done so because we saw what was out there and thought we could do it better and cheaper. And in fact it’s surprisingly easy to build a smart hoop if you have a little knowledge of electronics, some programming experience, and basic hand tools. Making hundreds of hoops and standing behind them for the duration of even a 6-month warranty is considerably more challenging, and there have been a number of notable failures.

Despite the animosity that erupted from time to time in public in the lead up to the campaign, at least three established hoop makers, myself included, approached Jonathan in private prior to the Kickstarter and tried to warn him about challenges he might not have foreseen. At least two other hoop makers had gone bankrupt in the prior year despite the best intentions and decent hardware. We even shared some information on competition-sensitive topics like failure rates of LED strips and the costs involved in warranty returns, but Jonathan was undeterred and went ahead with the Kickstarter with his original price, ship dates, and warranty.

The Prodigy hoops were to be the cheapest, most reliable, fastest to build, easiest to repair, most powerful, and most flexible hoops ever. In March 2016, before the end of the Kickstarter campaign, the design was said to be rivet-less, screw-less, and 100% user-serviceable, and the internal parts were ready for injection molds to be made.

Jonathan began posting photos on Facebook showing components in development, sometimes with dubious descriptions. One experienced hoop maker pointed out that the circuit boards in the photos Jonathan posted were in fact designed for a vastly less powerful 8-bit processor and not an ARM. Jonathan admitted to a little white lie and said those were early prototypes and that the new board was on the way, but at this point it started to appear that maybe not everything was on the level. Jonathan began posting updates only to a private backers-only Facebook group to avoid scrutiny.

In April, with the Kickstarter having far surpassed its original funding goal, Jonathan announced that he was taking the opportunity to invest in a new development that would yield a “1000% increase in reliability” and reduce hoop build time to “1/10th of the current time required”. The first batch of hoops, due that month, “could be looking at a minor delay”, but the rest of the hoops “should be able to be shipped well before the originally planned ship dates.”

The new development turned out to be the fabrication of custom ‘smart tubing’ for the hoops. Instead of a plain circular cross section, the tubing would have a thin channel molded in to hold the LEDs and eliminate the need for padding or support material.

Deadlines slipped by, and each setback was followed by promises of yet more features and improved specifications. The project was continually hyped and the issue became so divisive that the 25,000 member Infinite Circles Community on Facebook suffered a schism that it still hasn’t fully recovered from.

By late November it was said that the majority of the hoops were nearly done and the first batches were already being loaded on to UPS trucks. Some backers even received tracking numbers. In the end, exactly one hoop was delivered.

No one seems to know how or why this one particular backer was selected to be the first to receive a hoop. She declined to say much about the hoop and rumors spread that there was something wrong with it. In fact, Jonathan had asked her not to say anything about the hoop’s problems and her silence put her at the center of a social media firestorm. A stream of abuse, demands, and speculation led her to drop out of sight for a time. The hoop broke in short order and for more than a year she kept the controversial Protege, and it’s that hoop that I’ve analyzed today.

At various times the Protege was described as having up to 5 internal batteries, or a single non-removable battery and space for a removable battery. All of the hoops were to have been able to accept a 14500 size battery. In fact, this particular hoop takes a single removable 10440 size battery, which would give the hoop a useful run time of perhaps 30-60 minutes with typical patterns at moderate brightness – not quite the 9 hours once claimed.

After inserting the battery there was a delay of about 3 seconds before startup. Because this hoop arrived with only 8 LEDs working, I wasn’t able to test out any of its patterns or its menu system.

Custom laser engraving was one of many perks promised to the backers. That much, at least, was delivered, though it’s hard to make out and leaves a rough surface.

The Protege was claimed to be the lightest smart hoop ever, thanks to its 11/16″ smart tubing. This particular hoop, at 26″ ID, weighs in at 8.5 oz with no battery. For comparison, an unbalanced Hyperion of the same diameter is 8 oz. The Protege is more evenly balanced with the battery installed, but that’s almost entirely because of the smaller and lighter battery.

That ‘smart tubing’ is the first thing that really stands out about this hoop – and not in a good way. The hoop is pictured here laying flat on a table. Notice that the LEDs are not facing outward, and in fact they’re angled at about 45 degrees.

In June 2016, when I heard that there had been problems with the way the tubing was coiled, I predicted that this would be the doom of the project and I don’t think I was wrong. Even ordinary hoop tubing can be unruly, and extruding tubing with a non-uniform wall thickness and getting it to coil properly would require very careful attention during manufacturing. A hoop with the LEDs so far out of plane would never pass QA with any other maker, and this hoop was built months after the coiling problems were supposedly fixed. A hoop with ordinary tubing could have the LEDs re-seated, but this one’s going to be like this forever.

The tubing’s cross section is also noticeably out of round. 11/16″ tubing would ideally measure 0.6875″ all the way around. This tubing measures 0.675″ on its minor axis and 0.73″ on its major axis.

For all of the talk about laser-drilled pilot holes and 1/1000 mm precision, the button and screw holes are surprisingly rough. The nylon button didn’t come close to holding the hoop closed during the rigors of even normal hooping. The polycarbonate inner connector tube is also unusually short and you can see here that the hoop tubing is starting to flare out from the stress. This much distortion of the tubing would concern me on a hoop that had been in normal use for two years, and I don’t think this one was used for two months.

The polycarbonate connector with the LED strip running to the very end and a flex cable attached to the back is a design feature introduced by the Hyperion (and also apparently adopted by the newer Future Hoop models), but this version is glued together and lacks the Hyperion’s ability to remove the connector and controller without disassembling the rest of the hoop.

This view into the open battery compartment shows how far off axis the LED channel is. This also shows another problem inherent in the smart tubing: That channel extends through the entire length of the tubing and it has to be cut or reamed away to make room for the connector and other components.

“Smart hoop owners, just look inside your hoop and compare the difference between how much is inside that hoop compared to what the Protege is going to be like. It’s sooooo clean, no excess junk, no rattle, etc.”

The photo above shows the LED strip, the flex circuit that carries the IR receiver signals and negative battery connection, and the foam backing that supports it. Jonathan had railed against “…everything from custom supports, custom connectors, LED strips wrapped in packaging tape, tubes filled with foam and adhesive, and a bunch of other methods, some of which I’m not sure I understand the intended purpose of” in existing hoops. The Protege was supposed to escape that clutter, but seems to have fallen short.

The rattle is not as bad as some hoops, to be sure, but it’s there. Shaking the hoop vigorously produces a small but audible rattle. Smacking it with your palm produces a more noticeable rattle, apparently from the LED strip in its channel.

Here’s the connector in the closed position. The ends are a bit uneven, and the button is not a close fit for its hole, which seems to have been roughly chamfered by hand. Jonathan stated later that he’d switched to a steel button that he found more reliable. I wonder sometimes how many of us hoop makers Linda at Valco has taken sample orders from over the years – very possibly all of us.

The first time I opened the hoop I saw this and couldn’t figure out what the loose piece was for. It took me a second to realize it’s supposed to stay attached to the other end of the tubing. If it was glued in, it didn’t hold.

Disassembly of the hoop was difficult. There were three set screws to remove, but the guts didn’t want to pull free. Sometimes there’s a trick to these things and I spent a few minutes carefully pushing and pulling and wiggling, but despite my best efforts, in the end I accidentally tore some of the flex cable connections free when it did come loose. This wouldn’t be particularly significant if the Protege hadn’t been hyped as being 100% user-serviceable.

I’ve never seen an LED strip take a curve like that. Normally they really resist bending within the plane of the strip, but being in the angled channel has really stressed this strip sideways. The copper foil circuit is about 20% thinner than what we’re using on current Hyperions and buckles easily.

I’d also like to note that this is a totally stock APA102 strip and it matches exactly a sample I have in my LED collection. It’s not specially made for Prodigy as claimed. It’s also not at all waterproof, which was to have been one of the selling points. Jonathan posted photos of an LED strip with a superhydrophobic coating in a tank of water, and also claimed the LEDs would be “100% isolated from water damage” in their channel. This strip is uncoated and the ends of the channel were unsealed.

The LED strip seems to be glued in to the connector. Not a big deal if it never needs to be serviced, but that’s unfortunately not the case here. The design was also said to be without rivets, screws, or adhesives.

The foam backing used on the flex circuit is very much like that used on older Helix hoops. It’s square in cross section, squishy, and a bit on the heavy side. Those gaps have four IR receivers for the remote control, each in a 3D-printed carrier. It’s not clear what purpose the carriers serve. Recent Future Hoops have a similar layout with multiple IR receivers, but connected to a custom flex circuit that also carries the LEDs on the other side, to avoid extra wiring.

The extra receivers make the remote control reception more reliable, but the decision also says something about the design process for both of those hoops – namely that the programmers almost certainly relied on a common IR decoding library and never looked too closely at the details of the protocol. They both use the NEC protocol, which is ubiquitous but not a great choice for moving hoops because of the relatively long code bursts and the lack of redundancy in repeat codes. The hoop designers threw more hardware at the problem without fully understanding its cause.

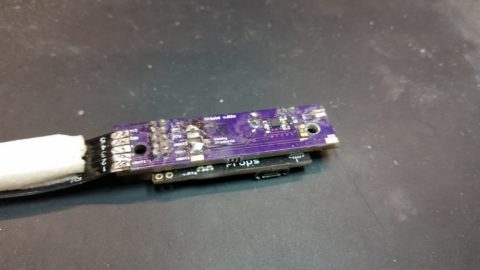

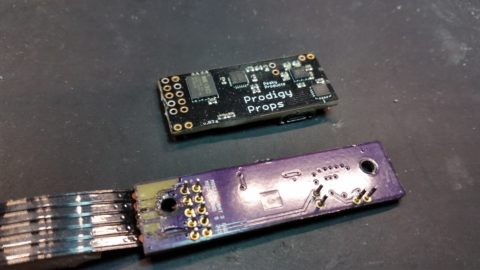

The Protege’s controller is actually two circuit boards, joined by permanently-soldered pin headers. I had to separate the two boards to try to repair the damage I caused, and it was a tedious task.

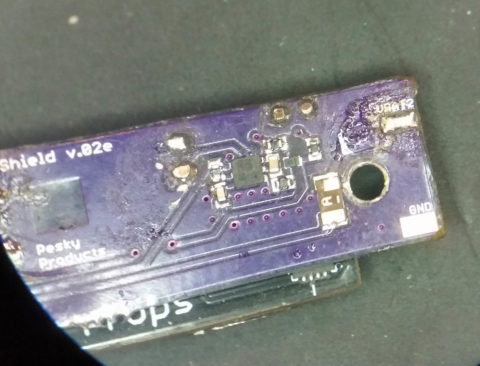

Here’s the other side. The microcontroller is a Kinetis MK20DX256, which has 32 kB of RAM and an ARM Cortex M4 core with a maximum clock frequency of 72 MHz. That’s well below the 168 MHz claimed – a claim that was made in a caption attached to a photo of this same controller. Its maximum bus clock speed is 36 MHz and its SPI module will do 12.5 MHz. This is significant because in May 2016 Jonathan claimed that the controller was capable of running 20,000 frames/second – a feat that would require the SPI module to run at more than 100 MHz for a 160 LED hoop.

The Hyperion and Flux controllers are both capable of running at 1,000 frames/second or more, but in production neither have been run at more than 500 because there’s simply no noticeable difference.

The Protege was claimed to have drag-and-drop file upload ability from USB. This board does indeed have a USB port on it, or rather part of one. It’s been partly cut off with a grinder. And more importantly, there’s no hole in the hoop tubing through which you could access the port. It does have the claimed 16 MB of flash memory, but no apparent way to access it, no provision for software updates, and no Arduino-based programming as the Kickstarter promised.

Out of curiosity I replaced the damaged connector and tried plugging it in. A tiny LED lit up to show it had power, but nothing else happened. It’s possible the software to make use of the USB port isn’t installed on this unit.

Here’s both of the boards together. The damage on the left side of the shield board was done when I disassembled the hoop. I’ve since patched around some of it, but the board is going to require more rehabilitation if it’s ever going to power up again.

The motion sensor on the board is an InvenSense MPU-9250. It’s a nice IMU, though it’s been out since at least 2014 and doesn’t seem to be quite as cutting-edge as implied in mid-2016.

If the soldering was done by hand, that’s not too bad considering the size. The purple solder mask is a dead giveaway that the board was made by OSH Park, my favorite low-volume PCB prototype maker. They don’t do assembly, though, and their boards are usually shipped separately and not panelized for automated assembly, so these components were almost certainly placed by hand. There’s also a fair amount of glue all over the board, probably to reinforce the wire connections, but it makes it messy and hard to work with.

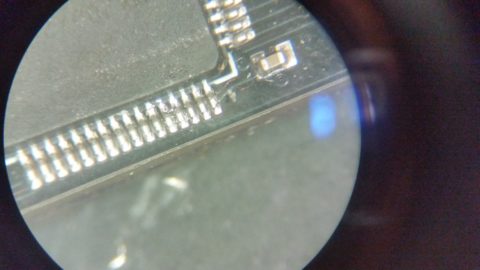

Looks like someone didn’t inspect this board closely. Right in the center you can see a solder bridge between two pins. They’re just general-purpose I/O pins and presumably not used in this layout so there’s no functional impact.

There was also a 3D-printed carrier for a button, which I broke while disassembling the hoop. All of the 3D-printed parts are made with a clear filament that seems unusually brittle, compared to the off-white ABS I’m used to. There was no sign of any custom injection molded parts described in the early days of the campaign.

Here’s the defect that doomed this particular hoop. The LED strip, despite being protected in its vaunted smart tubing channel, cracked all the way through 2 1/2 of the four traces. The rigid strip at upper left that’s glued to the LED strip, presumably to stiffen it, ends right there and creates a natural stress concentration.

This one photo says just about everything that needs to be said about the project. Jonathan was such a salesman that even I wondered at times if maybe he really could pull off something revolutionary, but it looks like he jumped into this without understanding the basics.

If this had been some random new smart hoop that showed up in my shop, minus the unusual tubing, I’d have posted a much less harsh review. I’d have said that it looks fairly typical of a new hoop maker’s first design, with fairly conventional construction, middle-of-the-pack controller specs, and a connector that’s going to need some work before it’s ready for volume production.

There was no way the Protege could match all of the hype, but I honestly expected more. Jonathan undoubtedly did a lot of work. Even if everything he posted photos of – hoop components, production automation software, customization software, fixtures, and packaging design – was nothing more than mock-ups and prototypes, he must have spent hundreds of hours on it.

I hope to be able to put this hoop back together and see it in action. It came with about a paragraph of instructions, though, so even if I get it running it’ll be hard to make any definitive statements about its capabilities.

At this point the chances of more Prodigy hoops shipping seems slim. Jonathan disappeared for well over three months last summer, and Prodigy Hoops LLC was disbanded by the state for failure to file an annual report and pay a $15 fee. In August, he resurfaced with a 40-minute video where he explained that earlier in the year his business partner had stolen all of the remaining Kickstarter money to support his heroin habit. Which could be true – I have no way of knowing one way or the other, but I do know that by then he was already in arrears with the electrical engineer he’d hired to develop the Protege’s electronics and it seems unlikely there was much money left to steal. It’s now been about four months since Jonathan was last heard from.

If he surfaces again, I expect we’ll hear another round of the same claims, that everything is still just on the verge of being perfect. Despite Kickstarter’s terms, we’re not likely to see an accounting of the $95,838 of backers’ money that was spent. And despite the promise of the hoop being 100% open source, not one line of code has been made public.

It’s not a magical unicorn hoop, and Jonathan is not a secret engineering genius. He’s an enthusiastic hobbyist and talented maker, like most of us started out, and what he’s accomplished is on par with a number of similar projects, though at considerable cost. With a clean slate he might even be able to compete in the smart hoop world, but after having blown through $95k already and owing roughly 400 hoops and three years of warranty support on them, it seems extremely unlikely that he’s going to resurface.

I’m told the Kentucky Attorney General has responded to backer complaints and is seeking more information and one backer is trying to coordinate a legal response, so this may not be the end of it even if Jonathan does try to stay hidden.

I’ll be sure to post an update if any more of this story unfolds.

Update: I’ve patched up the electronics and got it running again. I measured the actual frame rate at 268 frames/second, not 20,000. Only the power button on the remote seems to do anything, and it simply blanks the LEDs. It’ll drain the battery in under two hours that way, and it can’t be woken up using the remote.

Thanks

Thank you for taking the time out of your life to do this. I absolutely LOVE my Hyperion twins. I’ve had them since oct 2014 and they still work like a charm. The only reason I was getting twin protege hoops was bc they could come in a smaller size than the hyperions. That was literally two years ago and it’s been in limbo ever since. I appreciate you shedding some clarity in the subject.

Excellent teardown, Scott.

Bless you for this, I’ve already received my letter back from the Kentucky Attourney General. At this point everyone is so fed up, I feel bad for myself and fellow backers what we fell into this. And I’m positive it was more than the 95k as well because after Kickstarter was done, he took package upgrade payments from some. As well as some people deciding to double their orders when he kept telling us “here’s final forms, make any changes now! Last call” type bs.